Track Check

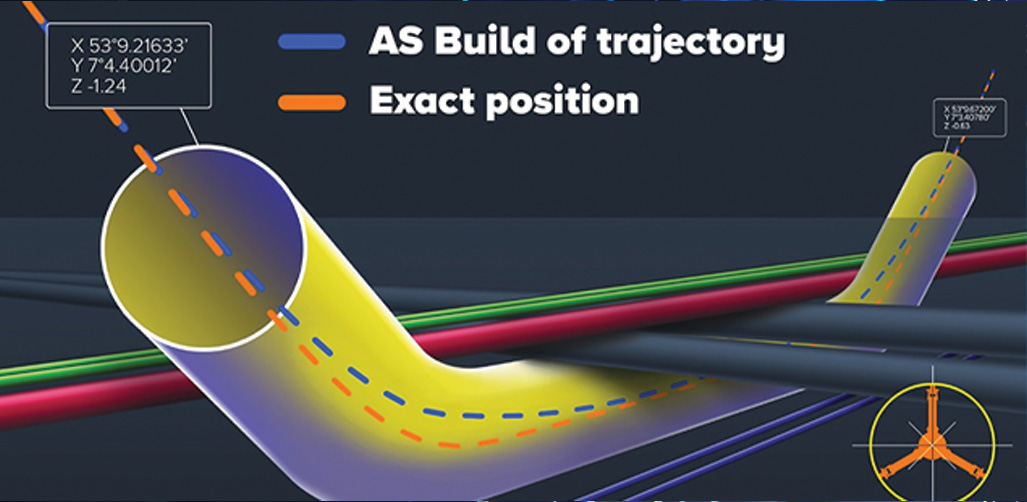

Track-Check Service Tells You Exactly Where Your Pipeline is Built

Track-Check provides real-time, highly accurate measurements of the as-build pipeline alignment following trenchless construction. Complete service offering from equipment supply and operation to drafting and a final certified drawing package.

Track-Check provides real-time, highly accurate measurements of the as-build pipeline alignment following trenchless construction. Complete service offering from equipment supply and operation to drafting and a final certified drawing package.

Leveraging advanced technology, Track Check ensures accurate and reliable pipeline measurements. Our innovative approach utilizes state-of-the-art gyro sensors to provide highly accurate measurements for as built and location verification of trenchless installed pipelines and conduit.

Trenchless Integrity Pipeline System (TIPS)

CCI has offered the TIPS product since 2018. TIPS is a system of protected conduits that are adhered to a pipeline before it is pulled into an HDD borehole. The conduits can then be used to house fiber optic leak detection or communication cables.

What is Track Check?

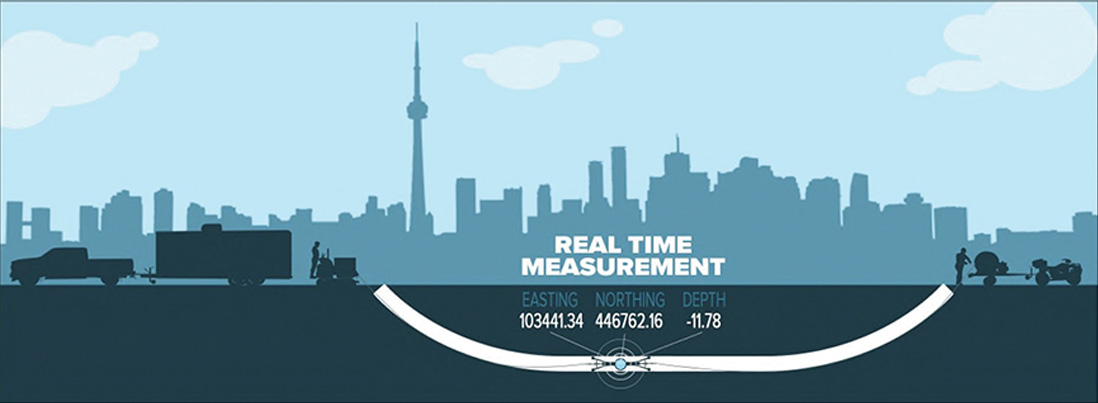

- Track Check is an as-built pipe survey system designed to survey the location of pipes installed via trenchless methods.

- Surveys are completed on pipes after pull-back and before tie-ins are completed.

- A gyroscopic survey tool is pulled through the pipe by winches on either side, taking measurements between two known points at set intervals

- Data is transmitted in real time to the computer system at surface.

- Gyroscopic survey tool is manufactured and calibrated by Brownline in the Netherlands.

Track Check Delivers Invaluable Benefits:

- Real-timed at a provided as tethered tool is pulled through the pipeline

- Highly accurate as-built documentation

- Pinpoint precise detection of pipeline locations

- Engineering analysis of survey data provided by CCI’s experienced trenchless engineering team.

CCI Offers Track-Check Services to Survey Pipes Installed via HDD or other Trenchless Methods

Track Check Solution

- Track Check surveys the true location of the pipe after it is installed.

- Track Check survey is referenced to independent survey coordinates at each end of the pipe.

- Track check survey provides full 3D data at more frequent intervals along the pipe than compared to typical pilot hole surveys.

- Higher data resolution allows for a more detailed engineering assessment to be completed on installed pipes.

- Grid coordinates provided with as-built data that is useable by a wider range of industry.