The evolution of fiber optic sensing technologies allows the industry to close the gap on detection and intervention of possible pipeline risks.

However, the technical Achilles heel of the fiber optic system is the cable itself. The cable is extremely fragile and optic cable designs must aim to give the best possible protection to the fiber itself from any external damage or influence. Moreover, the installation of fiber optics in harsh environments, such as trenchless crossings, is unlikely to survive during construction installation or over long operational periods. The TIPS system, developed by CCI, changes that.

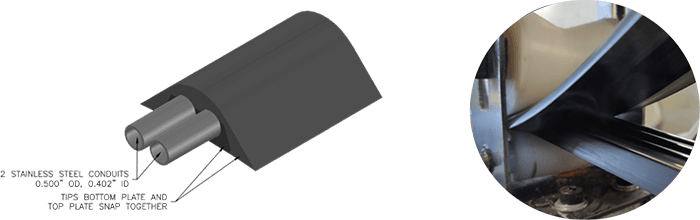

The use of CCI’s TIPS™ solves these issues by providing the most robust application of fiber optics designed for pipeline installation on the market today. TIPS™ consists of one or multiple internal high-tensile steel (0.5” diameter) conduit(s), encapsulated in a robust Thermoplastic elastomer protective cover that is contoured in a specific low-profile configuration (<1” tall) and completely bonded directly to the exterior of the pipeline.

This contoured TIPS™ conduit design provides a larger range to integrity monitoring usage. TIPS™ provides a solution which is easy to install, increases the success rate of any trenchless fiber optic install, provides a wider range of integrity detection (current and future) and allows for installation of multiple third-party integrity providers (optical and other).

The CCI TIPS™ system is tested to hold 150 psi for a minimum of 10 minutes and continuity is confirmed by passing an 8mm ball through each spool prior to delivery.

CCI Inc. has developed a proprietary two-part resin to securely bond the TIPS™ to the product pipe. A custom trailer mounted pump system has been developed for easier application of the resin to the TIPS™ and product pipe. The TIPS resin is suitable to install even during winter.